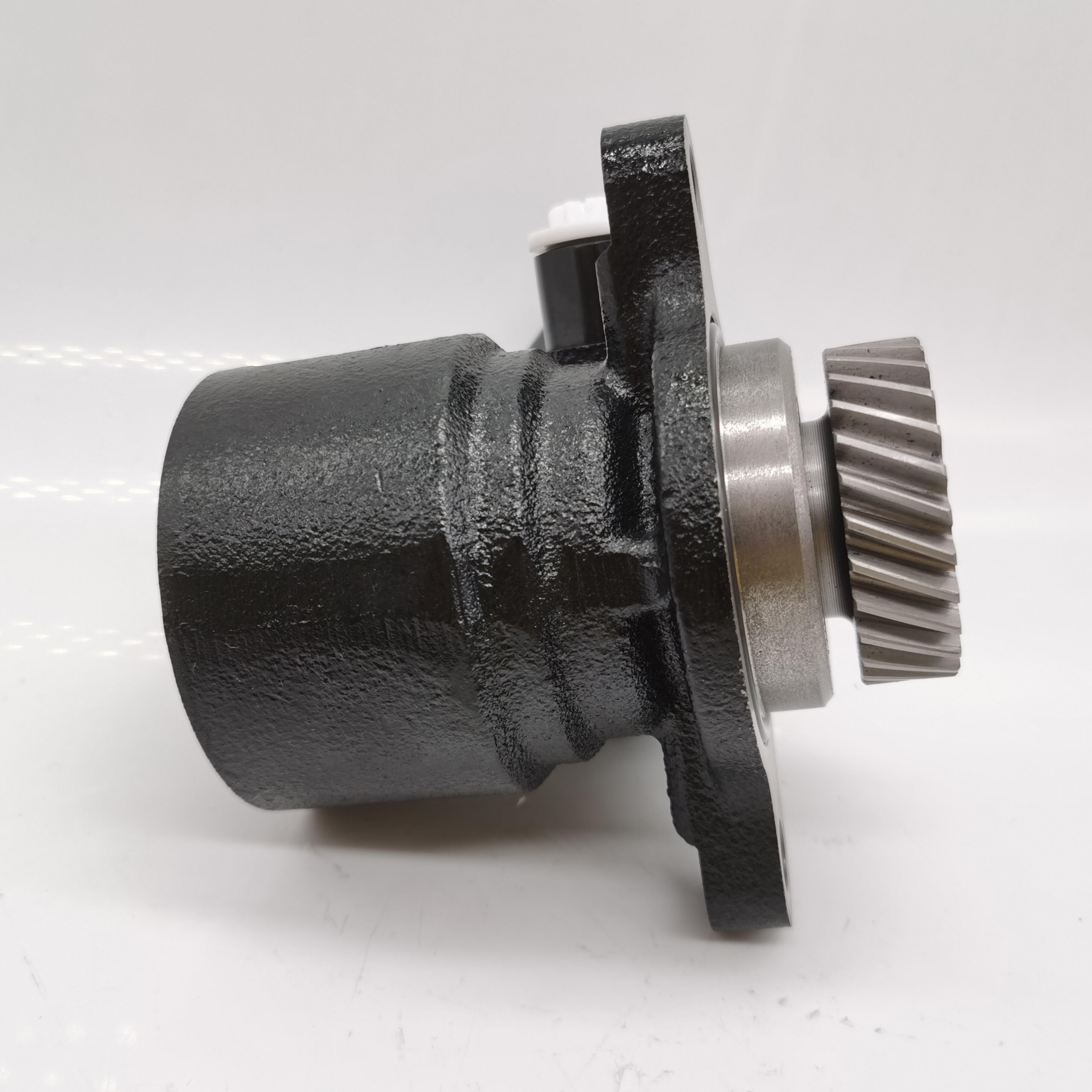

hydraulic pumps

As we discussed, a hydraulic pump is the heart of any hydraulic system and it converts mechanical energy into hydraulic energy. So, what you for example have to understand as regarding the main role of a hydraulic pump: is that it causes fluid move through a system and forces its flow from one point to another, which needs the use of either motor driven or in hand powered motor to be operational. Their technological features are that they can self-prime, manage a large variety of fluids, and operate at high pressures. Gear pumps, vane pumps, and piston pumps are some of the many types of these pumps; one will be more advantageous with respect to their individual properties. They are employed in construction and manufacturing, agriculture, automotive, etc. where they are used to drive machines such as excavators, lifts or hydraulic presses.

EN

EN

AR

AR

FR

FR

KO

KO

PT

PT

RU

RU

ES

ES