Superior Durability

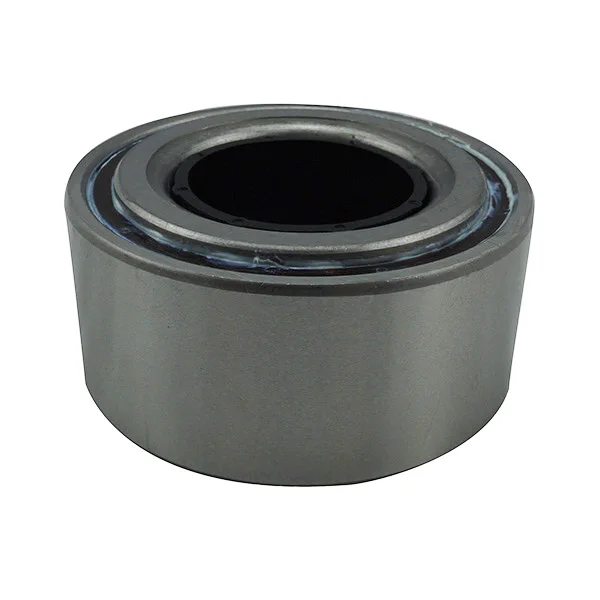

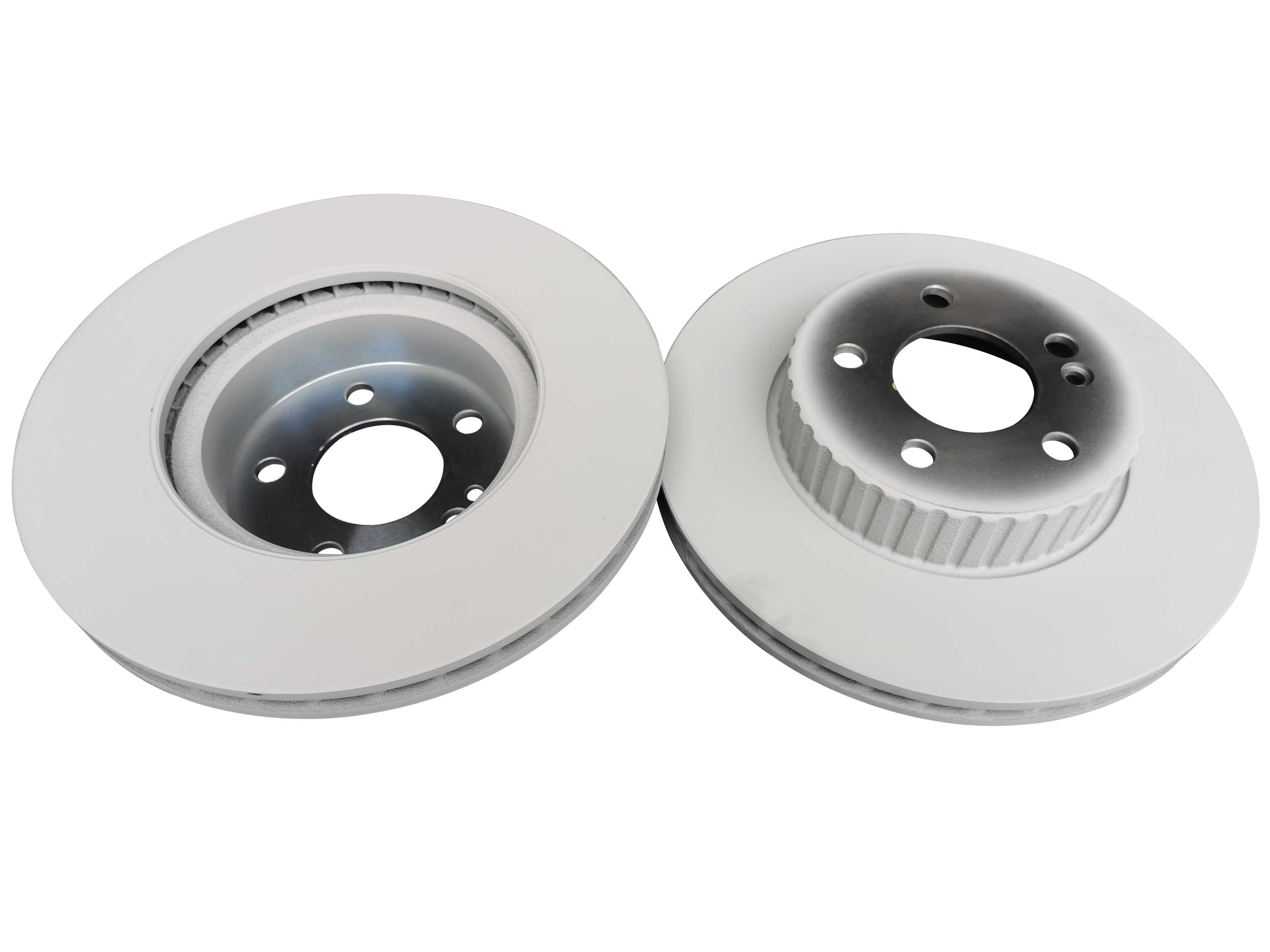

Moved them to start a new paragraph and convey the message.General cargo gear One of the features of the ring gear and pinion that is most outstanding is its exceptional durability. After use for several years, although exposed to the worst of conditions under loads of up to 300, 000 kg heavy load cargo (as shown below), this part still functions well. So during inspection it seems to have achieved exactly what was promised - long life and no damage at all when used like a watchword in practice.For the equipment, this durability means a longer working life, minimizing downtime and cutting costs for repairs. That in turn makes it possible to pursue uninterrupted work which takes major headaches out of operation considerations.Operations as usual, now meaning greater dependability, fewer interruptions: All of these things are welcome to customers.

EN

EN

AR

AR

FR

FR

KO

KO

PT

PT

RU

RU

ES

ES